TSMC’s 2nm Process: A Significant Leap in Semiconductor Technology

- Mass Production Milestone: TSMC’s groundbreaking 2nm process is now in mass production, marking a significant milestone in semiconductor technology.

- Innovative Transistor Architecture: The shift to GAA (Gate-All-Around) transistors signifies TSMC’s commitment to pushing the boundaries of chip performance and efficiency.

- Future Prospects: TSMC is exploring advanced materials like 2D and 1D, which could further revolutionize semiconductor development.

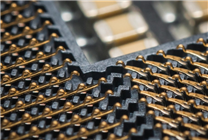

Recent developments in semiconductor technology have ushered in a new era, particularly with TSMC’s announcement regarding its 2nm process, which has officially commenced mass production. This latest advancement represents the first major upgrade in transistor architecture in over a decade, highlighting TSMC’s position as a leader in the industry.

The 2nm process is set to be the cornerstone of numerous next-generation chips, including AMD’s EPYC Venice processor, Apple’s anticipated A20 chip for the iPhone 18, Qualcomm’s Snapdragon 8E6 Pro, and MediaTek’s Dimensity 9600. To meet the anticipated demand, TSMC plans to escalate its production capacity from 35,000 wafers per month to an impressive 140,000 wafers per month within the coming year. This significant increase not only underscores the demand but also positions TSMC as a vital source of revenue in the semiconductor sector.

One of the most notable aspects of this development is the transition to GAA transistor architecture, marking a pivotal moment in TSMC’s 36-year history. The last architecture shift occurred in 2014 with the introduction of the 16nm process, which transitioned from planar to 3D transistors – specifically FinFET technology. This evolution in transistor design is particularly important as it allows for greater efficiency and enhanced performance in increasingly smaller semiconductor components.

TSMC’s rapid advancements have outpaced many competitors, notably Intel, which once projected a three-and-a-half-year technological lead over the industry. Intel commenced mass production of its 22nm 3D transistor process in 2011, with its first application in the IVB processor. In contrast, TSMC’s commitment to continuous innovation has established it as a reliable and swift mass-producer of advanced process technologies.

The future is even more promising, as the upcoming 1.6nm A16 process is expected to incorporate back power supply technology, which will enhance both density and overall performance. This is particularly advantageous for high-performance computing (HPC) products, where efficiency is paramount. Following the A16, TSMC is set to develop the 1.4nm A14 process, which will further refine both GAA and back power supply technologies.

Looking ahead, TSMC anticipates reaching the 1nm node, although no manufacturer has yet committed to mass production at this scale. The industry remains in the research and development phases for 1nm and smaller processes, where researchers are exploring CFET (Complementary FinFET) transistors to potentially improve packing densities and performance metrics.

In addition to the advancements in transistor design, TSMC is also investigating next-generation semiconductor materials, including 2D and even 1D materials. These explorations may hold the key to resolving challenges related to transistor miniaturization, enabling even further reductions in size and increases in performance. While TSMC is advancing in these areas, it must be noted that these technologies are still at an exploratory stage, and details on mass production timelines and specific performance benefits remain uncertain.

This commitment to innovation reinforces TSMC’s leadership position in the semiconductor industry, as the company continues to evolve and push the boundaries of what’s possible in chip manufacturing. With plans to enhance production capabilities and an eye toward revolutionary material developments, TSMC is not only shaping the future of technology but is also redefining the benchmarks for efficiency and performance in the global semiconductor market.

As technological advancements continue to emerge, stakeholders in the industry will be keenly watching TSMC’s next moves and how its innovations will influence the broader tech ecosystem. In a rapidly changing landscape, TSMC’s dedication to research and development promises a future filled with possibilities and groundbreaking technologies that will usher in a new era of semiconductor capabilities.