TSMC’s Future: Roadmap to Advanced Semiconductor Manufacturing

Key Takeaways:

- TSMC is progressing towards 1nm nodes, demonstrating leadership in semiconductor innovation.

- The roadmap reveals advancements in GAA technology and power efficiency.

- TSMC’s A14 process is projected to deliver an 80% performance improvement by 2028.

Introduction

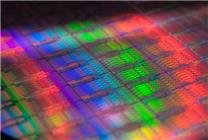

As the leading semiconductor wafer foundry, Taiwan Semiconductor Manufacturing Company (TSMC) continues to capture the industry’s attention with its ambitious development roadmap. With the transition towards sub-1nm nodes, the effectiveness and execution of TSMC’s plans will be pivotal in maintaining its competitive edge in the semiconductor landscape.

Insights from the Open Innovation Forum

At the recent Open Innovation Platform Ecosystem Forum, TSMC unveiled its logic process roadmap, focusing on advancements leading up to 2025. Currently, TSMC’s mass production standard is anchored at the 3nm FinFET technology, utilizing various iterations such as N3, N3E, N3P, N3X, and N3C.

Transitioning to Nanosheet Technology

The next milestone is the 2nm node, which for the first time will implement Nanosheet transistors—marking a significant shift towards Gate-All-Around (GAA) technology. The highly anticipated N2 process will begin production this year, setting the stage for AMD’s upcoming Zen6 architecture EPYC processor, expected to debut next year.

Future iterations, including N2P and N2X processes, are in the pipeline, but they’re set against the backdrop of the A16 Super Power Rail (SPR) process. SPR represents TSMC’s innovative approach to backside power supply, a technology positioned to outperform Intel’s PowerVia, though a direct comparison will only be possible once mass production kicks off.

The A14 Process: A Major Leap

The A16 process has evolved from what was originally planned as the 2nm node, demonstrating TSMC’s adaptive strategies in process development. Unlike competitors such as Samsung and Intel, who pursue simultaneous mass production of technologies, TSMC is strategizing a staggered rollout of GAA and power supply technologies.

Looking ahead, the A14 node is set for a substantial update, integrating GAA and backside power supply technology. This integration promises enhanced performance and energy efficiency, crucial factors for semiconductor applications in various industries.

Performance Improvements and Innovations

TSMC’s latest roadmap is a testament to its commitment to annual upgrades in process technology, aiming to sustain similar performance levels and improve energy efficiency across generations. Benchmarking against the 7nm node (N7) from 2018, TSMC has consistently shown performance improvements of around 15-18% with each successive node, while also reducing power consumption significantly.

The A14 process is expected to improve performance by 83% while enhancing energy efficiency by an impressive 3.2 times compared to the N7 standard. Over a decade—from 2018 to 2028—TSMC anticipates an overall technology improvement of approximately 80%. While this doesn’t fully align with historical projections from Moore’s Law, the industry recognizes the challenges in achieving such enhancements below the 28nm threshold.

Future Projections and Expectations

Taking a closer look at historical benchmarks, the prominent processor from TSMC’s N7 node was Apple’s A12, which featured a maximum frequency of 2.5GHz and 6.9 billion transistors. Fast forward to the present, Apple’s latest A18 Pro processor achieves frequencies of 4GHz with an impressive transistor count of 20 billion. With upcoming generations that will ultimately lead to the A14 process, we could potentially observe frequencies reaching 5GHz and transistor counts soaring to 30 billion.

Conclusion

TSMC’s roadmap reflects a bold vision for the future of semiconductor technology, highlighting its capacity for innovation and efficiency. The anticipated advancements in GAA technology and power supply solutions are set to redefine industry standards. As we edge closer to the sub-1nm era, TSMC’s developments will be critical not only for its future but for the entire semiconductor ecosystem.

By staying at the forefront of technology evolution, TSMC demonstrates its unwavering commitment to pushing boundaries and enhancing the capabilities of semiconductor manufacturing.