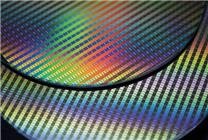

TSMC Advances 2nm and 1.4nm Semiconductor Processes: A Path to Innovation

Summary:

- TSMC is on track to begin mass production of its 2nm process while accelerating the development of its 1.4nm technology.

- The semiconductor giant is investing heavily in new factories to bolster production capabilities.

- Risk trial production for the 1.4nm process is expected to start in 2027, with the goal of achieving full mass production by 2028.

On January 2, it was reported that Taiwan Semiconductor Manufacturing Company (TSMC) has made significant strides towards mass production of its anticipated 2nm process. Driven by robust market demand, TSMC faced tight wafer supply, prompting plans for the construction of three additional factories to ensure it meets increasing customer requirements.

Simultaneously, the development of TSMC’s 1.4nm manufacturing process is progressing on schedule. Notably, TSMC is expediting construction efforts for this facility, which is critical to the company’s ongoing advancement in semiconductor technology. Current projections indicate that risk trial production for the 1.4nm process could initiate as early as 2027.

Risk trial production refers to the preliminary small-scale production of new products aimed at identifying potential challenges within the manufacturing process, such as yield and performance levels. This stage is crucial for evaluating the production system’s stability, thereby minimizing risks associated with full-scale manufacturing.

The foundation work for TSMC’s new 1.4nm plant began in early November 2025. Situated in Taiwan’s Science Park, the facility plans to encompass four factories along with support office buildings. The initial investment for this ambitious project is projected at NT$1.5 trillion, and once operational, the mass production target is set for 2028.

It is estimated that the newly established factories will generate a collective revenue of approximately US$16 billion in their first operational year while creating between 8,000 to 10,000 job opportunities, thereby contributing to local economic growth.

While precise details on potential customers adopting the 1.4nm technology have yet to be disclosed, previous insights suggest that Apple has secured a significant share of TSMC’s initial 2nm production capacity for its forthcoming A20 and A20 Pro chips. Given this relationship, it is plausible that Apple will leverage the advantages of TSMC’s cutting-edge 1.4nm process once it becomes available.

One crucial aspect of the 1.4nm process to consider is the expected initial yield, which will likely not exceed 20%. However, as production progresses, yields are anticipated to improve alongside a projected surge in market demand.

In summary, TSMC’s commitment to pioneering semiconductor technology is evident in its ambitious plans for both the 2nm and 1.4nm processes. As the industry anticipates the capabilities afforded by these cutting-edge technologies, the semiconductor giant is strategically positioning itself to lead the market in innovation, ensuring its products meet the evolving needs of global consumers.

By focusing on advanced manufacturing processes and making substantial investments, TSMC is set to not only enhance its production capabilities but also solidify its status as a leader in the semiconductor industry. The upcoming years will be pivotal in determining how these new technologies will reshape the landscape of consumer electronics and beyond.