Micron Technology’s Multi-Billion Dollar Investment in Japan’s Semiconductor Industry

Key Points:

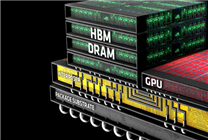

- Micron Technology plans to invest about 1.5 trillion yen (approximately $9.6 billion) to build a dedicated factory for high-bandwidth memory (HBM) chips in Hiroshima, Japan.

- The factory is set to break ground in May 2024, with production expected to commence by 2028, aimed at diversifying supply chains.

- The Japanese government is poised to support this initiative with subsidies up to 500 billion yen, enhancing Japan’s appeal to international chip manufacturers.

In a significant move for the semiconductor sector, Micron Technology is set to invest around 1.5 trillion yen (roughly $9.6 billion) in constructing a new factory at its existing facility in Hiroshima, Japan. This factory will specialize in the production of high-bandwidth memory (HBM) chips, which are crucial for the growing demands of artificial intelligence (AI) applications.

Launch Timeline and Strategic Goals

Construction is anticipated to commence in May 2024, with the facility expected to begin production by 2028. This strategic investment marks Micron’s first major new factory project since 2019, reflecting the rapidly increasing demand for HBM driven by advancements in AI and data center technologies. By expanding its manufacturing footprint in Japan, Micron aims to diversify its production bases and reduce reliance on Taiwan, where a significant portion of advanced chip manufacturing is currently concentrated.

Government Support and Economic Implications

To further boost its semiconductor industry, Japan’s Ministry of Economy, Trade and Industry is prepared to offer up to 500 billion yen in subsidies for this project. This governmental backing is part of Japan’s broader strategy to attract leading international chip manufacturers, such as Micron and TSMC, to invest more heavily in the region.

Micron’s decision to establish a new facility aligns with the Japanese government’s efforts to solidify its semiconductor sector and enhance resilience against global supply chain disruptions. By encouraging investment through substantial financial incentives, Japan hopes to regain its standing as a key player in the global semiconductor landscape.

Enhancing Competitive Position

Historically, Micron’s production capabilities for HBM have largely been concentrated in the United States and Taiwan. However, as the push for AI technologies intensifies, the demand for high-performance memory chips is surging. The company’s expansion into Japan is not only a response to market needs but also a competitive strategy against industry leader SK Hynix.

By spreading its manufacturing across different global locations, Micron is working to bolster its supply chain resilience. The move is expected to mitigate risks associated with political tensions and natural disasters that could disrupt operations in any single region.

Technological Advancements

In May of this year, Micron took a substantial step toward advanced manufacturing at its Hiroshima site by incorporating extreme ultraviolet (EUV) lithography equipment. This high-end technology is essential for creating next-generation HBM, specifically the anticipated HBM4. The integration of EUV processes will enable Micron to enhance the performance and efficiency of its memory chips, ensuring they meet the evolving requirements of industries focused on AI and high-speed computing.

Conclusion

Micron Technology’s investment in a new HBM factory in Japan represents a pivotal shift in the semiconductor industry. By diversifying its production capabilities and leveraging government support, Micron is positioning itself for future growth in a sector that is critical to technological advancement. The strategic implications of this investment extend beyond Micron, potentially revitalizing Japan’s semiconductor ecosystem and establishing the country as a stronghold for future innovations in memory technology.

This initiative underscores the importance of adaptive strategies in the semiconductor market, highlighting the need for companies to align their operations with global demands while ensuring supply chain stability in an increasingly interconnected world.