Intel Faces Supply Challenges Despite High Demand for Processors

Summary:

- Intel’s latest processors, Arrow Lake and Lunar Lake, are experiencing supply shortages due to conservative wafer orders.

- The company relies on TSMC’s advanced manufacturing capacity, which is currently fully utilized.

- Intel is optimistic for increased supply in the coming quarters but remains uncertain about meeting overall demand.

In a recent announcement, Intel executives highlighted the persistent challenges regarding the supply of its client and data center processors. John Pitzer, Vice President of Corporate Planning and Investor Relations, emphasized the company’s difficulty in keeping pace with market demand. He poignantly stated, "If we have more Lunar Lake wafers, we can sell more Lunar Lake; if we have more Arrow Lake wafers, we can sell more Arrow Lake," underscoring the direct relationship between production capacity and sales potential.

Key Factors Influencing Supply Constraints

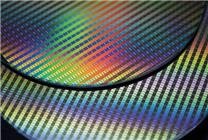

The ongoing supply constraints primarily stem from Intel’s approach to wafer orders for its Arrow Lake and Lunar Lake processors. These logic chips are currently outsourced to TSMC (Taiwan Semiconductor Manufacturing Company). According to Pitzer, Intel’s initial wafer orders were overly cautious, limiting their production capabilities.

Both the Arrow Lake and Lunar Lake processors utilize TSMC’s cutting-edge N3B 3nm manufacturing process. However, TSMC’s advanced fabs are often operating at full capacity, making it increasingly difficult for Intel to secure additional capacity allocations. This tight manufacturing landscape directly impacts Intel’s ability to fulfill its processor supply commitments.

Anticipated Supply Improvements

Despite these challenges, Intel has expressed hope for improved supply in the fourth quarter and beyond. However, Pitzer cautioned that it remains uncertain whether these improvements will be sufficient to address the backlog of demand. He noted, "The majority of our current capacity is still on Intel 7 (10nm), which is why we are most nervous in those areas," indicating that their older manufacturing process still dominates current production capabilities.

Pitzer also acknowledged that the company could further benefit from additional Granite wafers, stating, "To be honest, if we have more Granite wafers, we can sell more." This frank admission highlights the ongoing struggle for Intel to align production with the high demand characteristic of the semiconductor market today.

Future Outlook and Strategic Adjustments

Looking forward, Intel is navigating through a landscape filled with supply chain complexities and competitive pressures. As the global market continues to witness rapid technological advancements, the ability for companies like Intel to respond swiftly to demand fluctuations is crucial for maintaining market share and customer loyalty.

Intel’s strategy will need to focus on enhancing partnerships with foundries like TSMC while also exploring opportunities to bolster in-house manufacturing capabilities. Diversifying sourcing options and improving production efficiencies could prove vital in mitigating risks associated with future supply chain disruptions.

Conclusion

In conclusion, Intel’s current predicament illustrates the intricate relationship between semiconductor production capabilities and market demand. As the company gears up for increased supply in the upcoming quarters, the focus on strategic enhancements in manufacturing processes and wafer sourcing will be paramount for meeting consumer expectations and sustaining growth.

In summary, the supply constraints affecting Intel’s next-generation processors underscore the broader challenges within the semiconductor industry. As the demand for cutting-edge technology continues to escalate, the importance of robust manufacturing capabilities cannot be understated. Intel’s path forward will require a continuous evaluation of its production strategies to remain competitive in an ever-evolving landscape.