Summary

- Intel’s shift from developing external foundry processes to focusing on internal development for the 14A node highlights evolving industry strategies.

- Initial feedback on the 14A process indicates promising reception from external customers, paving the way for future advancements.

- With plans to launch new process nodes biennially, Intel aims for significant improvements in energy efficiency and power consumption.

Intel’s Strategic Shift to 14A Process Development

On October 26, Intel revealed a significant pivot in its manufacturing strategy, initially intended to champion external foundry development with the 18A process node. However, progress has been less than optimistic, prompting a transition to focus on internal utilization and the development of the 14A foundry process.

In good news for the semiconductor giant, Intel announced that "initial feedback from external customers on the 14A is encouraging." Although Intel has not disclosed specific foundry customers, this feedback hints at a positive reception that could bolster its manufacturing ambitions.

Overview of the 14A Process

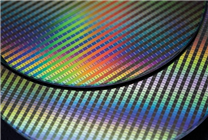

The 14A process, announced in early 2022, is crucial for Intel’s roadmap. Often equated to a 1.4nm technology, it is expected to enter mass production around 2027. This innovative process is distinct from prior iterations; developed in collaboration with external partners from its inception, 14A is optimized for high-performance computing (HPC), artificial intelligence (AI), and mobile applications. Notably, this process is anticipated to improve energy efficiency by 15-20% while reducing power consumption by 25-35%.

Cutting-Edge Technology

Intel’s 14A process will deploy a groundbreaking High NA EUV (Extreme Ultraviolet) lithography machine, marking a first in the industry. Valued at approximately $400 million, this machine is 1.5 to 2 times costlier than existing options. Intel has successfully secured the first unit of this advanced machinery, currently being tested at its Oregon facility, showcasing the company’s commitment to pioneering technology in semiconductor manufacturing.

Future Development Plans

Looking ahead, Intel plans to introduce a new process node every two years, along with evolutionary versions of each node. This strategic approach aligns with Intel’s goal of achieving breakeven for its foundry business by 2027. The company’s dedication to continuous innovation is evident as they anticipate that each new node will enhance performance and efficiency metrics.

Conclusion

Intel’s transition to focus on the 14A process indicates a dynamic shift in strategy, emphasizing internal development over external partnerships. With promising early feedback and groundbreaking technology at its disposal, the company is poised to enhance its competitive edge in the semiconductor industry. As Intel gears up for its next developments, the integration of advanced manufacturing technologies and a commitment to sustainability will play pivotal roles in shaping its future endeavors.