Advancements in Semiconductor Technology: A Look into the Future of 2nm Processes

Summary

- Domestic semiconductor processes are evolving towards the 2nm level, relying on DUV lithography despite challenges.

- Huawei’s innovations, particularly in self-aligned quadruple patterning (SAQP), show promise for achieving significant advancements without EUV technology.

- Continuous patent developments underscore a commitment to advancing semiconductor technology while countering external pressures.

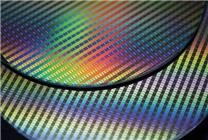

In recent reports, the semiconductor industry is approaching a significant milestone: the potential to develop processes at the 2nm node using DUV (Deep Ultraviolet) lithography techniques. As the trend shifts towards extreme ultraviolet (EUV) lithography for nodes below 5nm, the development of DUV technologies remains crucial, particularly for domestic manufacturers aiming for innovation in a constrained landscape.

The DUV Challenge

For several years, the limitations associated with DUV lithography became increasingly apparent, particularly at the 7nm node. However, research and development in the domestic semiconductor community indicate that the progression to 2nm is not only plausible but also within reach. Industry experts emphasize that even in the face of external sanctions, the pursuit of DUV lithography’s capabilities will continue unabated.

A significant breakthrough occurred when Huawei introduced its research on SAQP technology in 2021, laying the groundwork for achieving 2nm processes without relying on EUV lithography. The SAQP method, utilizing DUV machines, allows for the production of chips with gate pitches lower than 21nm—an essential threshold for the 2nm node.

Clarifying Terminology

It is crucial to address a common misconception within the industry: SAQP is often misinterpreted as quadruple lithography. This distinction is vital; quadruple lithography is technically and economically unfeasible in the current landscape. The differentiation between SAQP and quadruple lithography is not just semantic but underscores the practical viability of these technologies in advancing semiconductor manufacturing.

Beyond 2nm: The Innovation Pipeline

Huawei’s ambitions extend beyond just establishing a 2nm process. The company is actively applying for patents concerning GAA (Gate-All-Around) surround gate transistors and CFET (Complementary FET) technology, which are viewed as pivotal for pushing semiconductor technology beyond 1nm and potentially down to 0.1nm nodes. These innovations signal that domestic developers are not merely keeping pace; they are strategically preparing to leapfrog internationally recognized competitors.

While these patents are predominantly of a technological nature, indicating a proactive stance in semiconductor R&D, they do not guarantee immediate mass production. However, they demonstrate a long-term commitment to enhancing capabilities and deepening exploration within advanced technologies.

Competitive Landscape and Future Implications

One of the most compelling aspects of this development is the comparative analysis of production methods. As domestic manufacturers work towards realizing 2nm chips with DUV techniques, international companies like TSMC, Samsung, and Intel are continuing their reliance on costly EUV or High NA EUV lithography. This raises critical questions about competitive sustainability: which party is more susceptible to a loss of competitiveness in a rapidly evolving semiconductor landscape?

The strategic decisions made today will have profound implications for future advancements and economic viability. The ability to develop cutting-edge technologies domestically not only shields domestic manufacturers from external pressures but also reinforces their position in the global chip market.

Conclusion

The transition towards 2nm semiconductor processes through DUV lithography, backed by innovative technologies like SAQP and cutting-edge research on new transistor designs, signifies a pivotal moment for domestic semiconductor manufacturing. As the industry navigates through complex challenges and opportunities, the future looks promising. The efforts made today could establish new benchmarks in semiconductor capabilities, ultimately defining the competitive landscape for years to come.

By investing in advanced research and fostering an ecosystem conducive to innovation, domestic players are not just adapting but are poised to lead in the global semiconductor arena.