Intel’s 14A Process: A Potential Game Changer in Chip Manufacturing

Summary Points:

- Intel’s 14A process shows significant advancements in energy efficiency and power consumption.

- The future of pure American chip manufacturing heavily relies on Intel, despite increasing foreign investments.

- Positive external evaluations suggest a solid foundation for Intel’s upcoming technology.

Intel’s latest developments indicate a promising trajectory for American chip manufacturing, even as global giants like TSMC and Samsung ramp up investments under U.S. pressure. Despite these multinational efforts, the core technologies remain largely proprietary, emphasizing the vital role Intel plays in sustaining U.S. chip production.

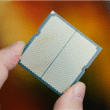

Advancements with the 14A Process

Intel is currently in the spotlight with its 14A process, which is expected to represent a significant leap in semiconductor technology. Notably, this process employs second-generation Gate-All-Around (GAA) transistor technology, coupled with a transition to a more efficient PowerDirect back contact power supply. Enhancements also include the utilization of High NA EUV lithography machines, marking a substantial technical upgrade.

Early findings showcase that the 14A process surpasses its predecessor, the 18A, in several key metrics:

- Energy Efficiency: Improvement by 15-20%

- Chip Density: An increase of 30%

- Power Consumption: A notable reduction of 25-35%

These improvements not only highlight Intel’s technical prowess but also set the stage for a much more competitive edge in the semiconductor market.

Strong External Validation

Recent assessments from external clients have validated Intel’s efforts. Many users have commented favorably on the performance enhancements of the 14A process. Such positive feedback reflects well on Intel’s reputation and promises a collaborative future with potential external partners.

Intel’s executive team has highlighted the competitive edge of the 14A process, claiming that its performance will significantly exceed that of the 18A process within the same timeframe. This assertion is backed by comprehensive data supporting considerable advancements in both efficiency and capability.

Looking Forward: Mass Production Goals

Currently, the 0.5 Process Design Kit (PDK) of the 14A process has been released, though an official version is still in development, with mass production being targeted for 2028. The CEO has signaled that 2024 will be a pivotal year in shaping the company’s operational decisions, particularly concerning investments in new manufacturing facilities. Engaging large external clients will be crucial for Intel’s strategic planning moving forward.

Conclusion

As the landscape of chip manufacturing evolves, Intel stands at the forefront of innovation within the United States. The advancements seen with the 14A process not only demonstrate the company’s commitment to excellence but also underline its importance in achieving a self-reliant American semiconductor industry. With solid external validations and promising technical upgrades, Intel is poised to reshape the dynamics of chip manufacturing significantly.

In summary, while global competitors may increase their investments and capabilities, Intel remains a cornerstone of American chip technology, ready to take substantial leaps forward in the coming years.